Our company provides clients with complex fertilizer complete sets of equipment technical service, after many years of research and development experience of the compound fertilizer granulator equipment manufacturing , and the meticulous manufacture of hi

This machine is one of the main (biological) organic fertilizer production equipment produced by our company. It is the fertilizer machinery which has been studied, improved and carefully manufactured on the basis of advanced granulating machine at home and abroad.

This series of granulator is a new patented product developed by our company and the Agricultural Machinery Research Institute. It is designed and manufactured by the new technology of wet continuous push rod granulation.

The multifunctional flat die pellet machine is a common used equipment in the production of organic fertilizer. It can produce cylindrical organic fertilizer particles and feed particles. It can also connect polishing equipment, make cylindrical particles t

Crop straw crusher can crush corn straw, straw, peanut skin, beanstalk, flowers and other burning residues. It avoided the burning of crop straw, protected the environment, and effectively developed renewable energy. The machine is reliable in operation,

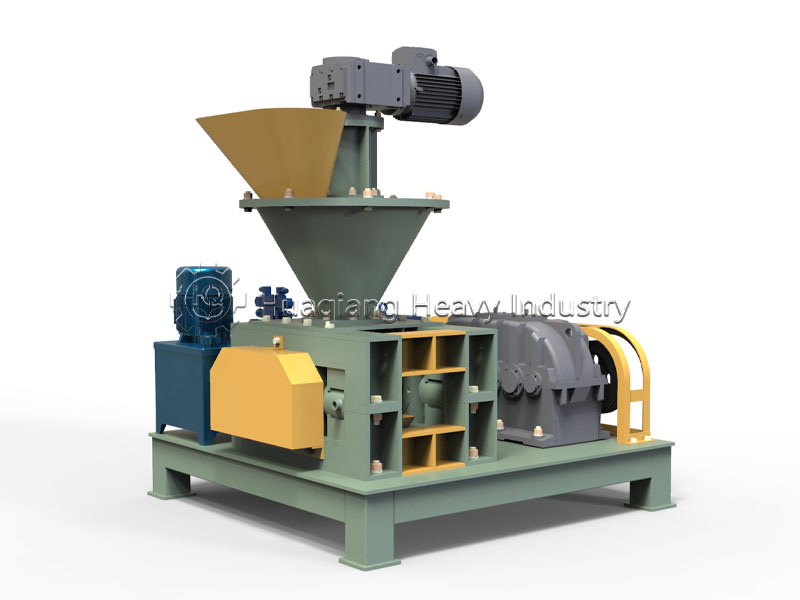

Chain fertilizer crusher is suitable for the fragmentation of organic fertilizer and compound fertilizer blocks during production process, also widely used in chemical, building materials, mining and other industries. In the process of crushing, we use sy

Half-wet material crusher is an advanced smashing technology at home and abroad, which has been researched, improved and manufactured by many years of production experience, It combined with many years of machines production experience of our factory. Thi

Cage fertilizer crusher belongs to medium-sized horizontal cage mill. It can crush all kinds of single chemical fertilizers with water content below 40%, especially for materials with high hardness.

This series of horizontal mixer is a new kind of mixing equipment which made by our company. The machine has the advantages of high mixing degree and little residue, so that it is suitable for mixing the organic fertilizer and inorganic fertilizer.

The machine is a new type of vertical mixer. It is composed of a stirring plate, a feed outlet, a stirring arm, a rack, a gear box and a transmission mechanism. The machine is characterized by the driving shaft of the reducer, which makes it run, the stir

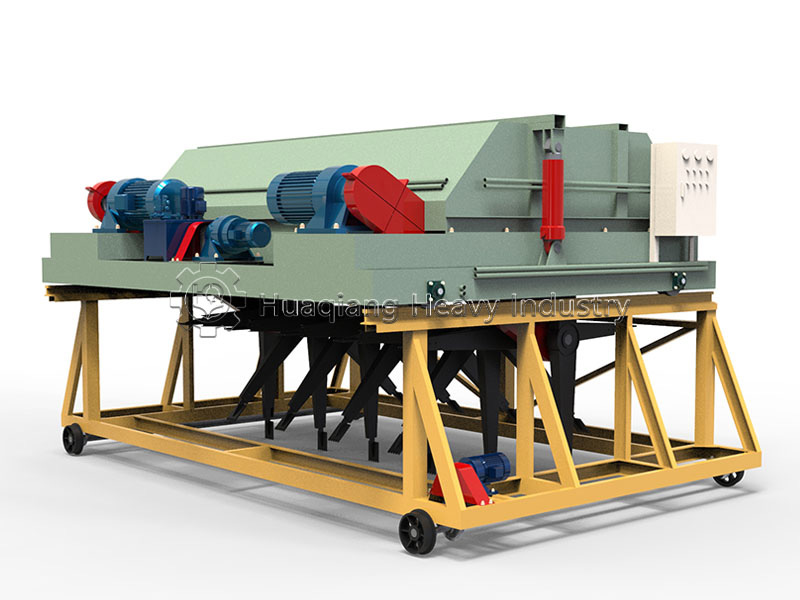

The double shafts mixer is rotated by two sets of axles with spiral blades, adding water to wet, stir and transport the powdery materials to make the powdery material reach the controllable humidity. This equipment is mainly applied to the humidification

This series of BB fertilizer equipment is a new generation of hybrid equipment developed by our company. The most prominent advantage of the machine is that the mixing amount is large, the formula is convenient and the pertinence is strong. It overcomes t

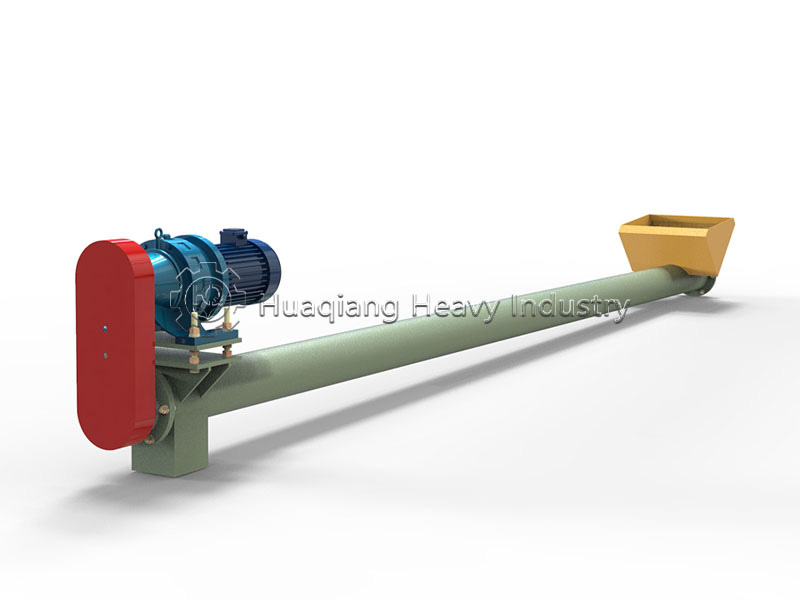

The screw conveyor is a product designed by our company, which combines the experience of all kinds of screw conveyor at home and abroad. The product can meet the transportation of various materials and be matched with all kinds of mixing machines.

Compared with the ordinary belt conveyor, it increases the mobile device, because the mobile device makes the mobile belt conveyor with the superior maneuverability, and can be driven or traced to the suitable place for loading and unloading of goods acco

Belt conveyor is widely used in metallurgy, mine, coal, port, transportation, water and electricity, chemical and other departments to carry on, loading, reloading or accumulating all kinds of normal temperature, loose density of various kinds of bulk, du

This series of products is mainly suitable for high inclined continuous conveying of bulk materials. With the conveyor belt with corrugated side plate and diaphragm plate, the transmission angle is 0 ~ 90°.

The vibrating screen machine is specially designed and developed by our company for screening compound fertilizers. The sieves are divided into two types: single layer and double layer. The mesh is made of high quality manganese steel with simple structur

Rotary screen is a common equipment in the production of compound fertilizer, which is mainly used for the separation of finished products and reclaimed materials, and can also realize the classification of products, so that the finished products can be e

Automatic quantitative packaging for powdery materials in flour, starch, feed, fertilizer, food, chemical industry, light industry, building materials and other industries.

Automatic quantitative packaging for ton bags materials in flour, starch, feed, fertilizer, food, chemical industry, light industry, building materials and other industries. The main features of the organic fertilizer ton bag packaging machine: 1. Tailored and designed for the respective characteristics of the powder materials and the different requirements of the manufacturer. The equipment is advanced in technology, durable and has few wearing parts. 2, feeding, packaging stepless speed regulation, equipment performance is stable, packaging accuracy and speed. The ton bag packaging ma

Automatic quantitative packaging for granule materials in flour, starch, feed, fertilizer, food, chemical industry, light industry, building materials and other industries.

The coating machine is composed of screw conveyor, stirred tank, oil pump and main engine. Powder dusting or liquid coating process can effectively prevent the agglomeration of compound fertilizers Can effectively prevent the agglomeration of organic fertilizer. Polypropylene lining or acid-resistant stainless steel is used in the main unit. This equipment has been specially designed on the internal structure according to the process requirements, and is an effective special equipment for organic and inorganic fertilizers.

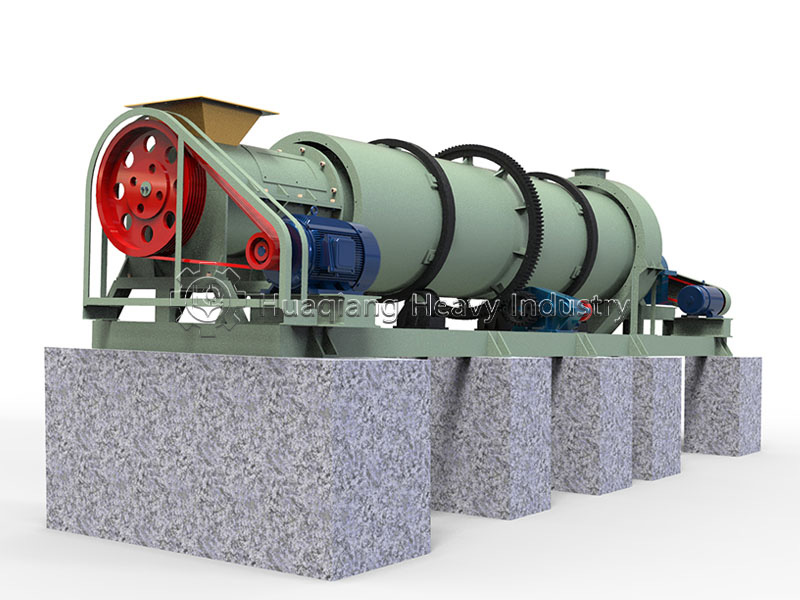

The rotary dryer is a new generation of rotary drum dryer developed by our staff for many years of compound fertilizer production experience. It has the characteristics of beautiful appearance, simple operation, low energy consumption, long service life,

Drum cooler is a new generation of high efficiency cooling machine developed by our staff for many years of compound fertilizer production experience. It is paired with the rotary drum dryer for cooling the fertilizer particles in a certain temperature

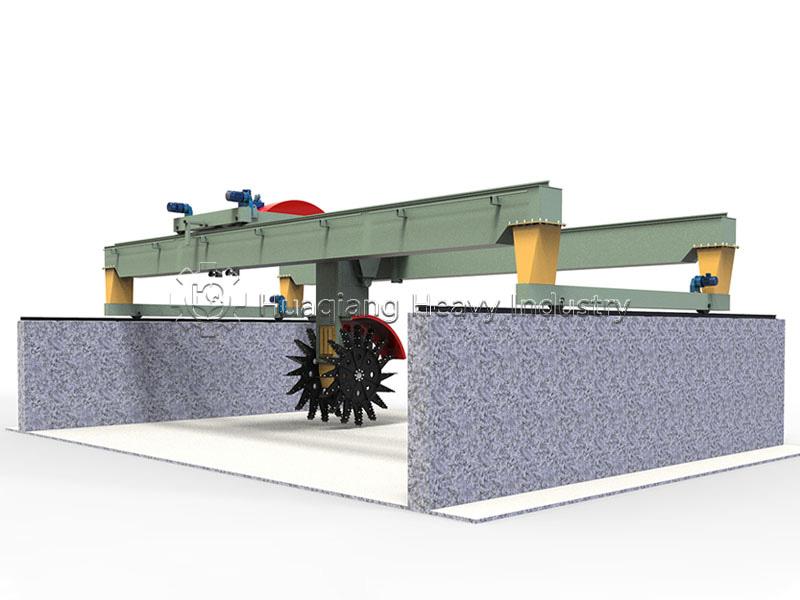

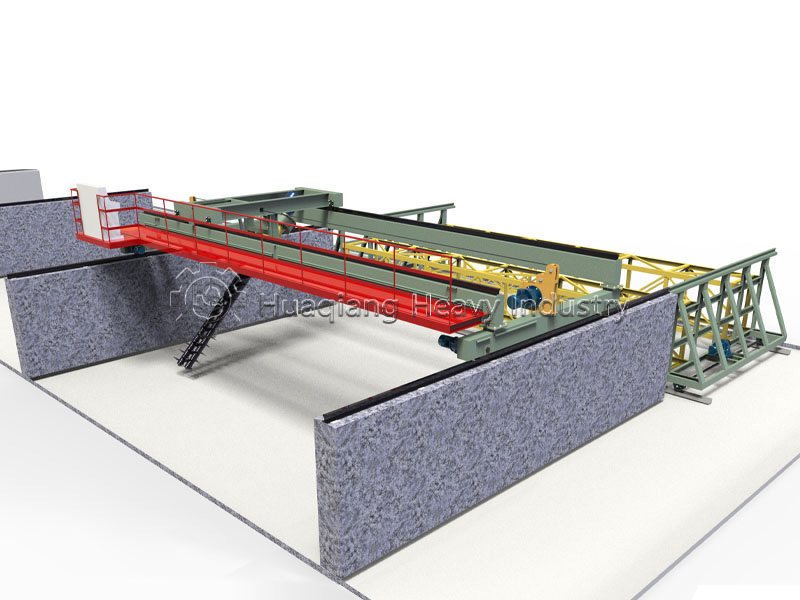

The chain-type turning machine is a core equipment widely used in the fields of organic fertilizer fermentation, solid waste treatment, etc. Its core function is to achieve uniform turning of materials, ventilation and oxygen supply, and accelerated composting through chain conveying and turning operations.

The large wheel compost turner is a key equipment in the fields of agricultural environmental protection and organic fertilizer production. Its core function is to efficiently turn, stir and aerate the piled organic waste (such as livestock and poultry manure, straw, mushroom residue, sludge, etc.), accelerate the composting process of the materials, and at the same time achieve deodorization, sterilization and moisture content adjustment, and finally convert it into high-quality organic fertilizer.

The double-screws turning machine is used for fermenting and dump of organic wastes such as livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust.

The fermenting and dumping of organic wastes, such as livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust, they are widely used in the fermentation and removal of water in organic fertilizer plant, compound fertilize

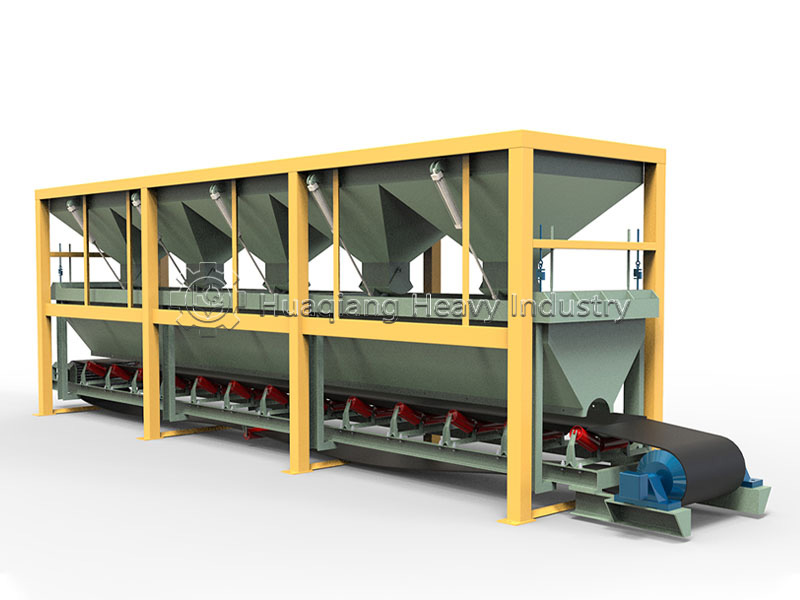

It is mainly used for the mixing, batching and feeding of 3-8 kinds of materials. The machine adopts computer scales for automatic control, and uses pneumatic valves to control the main material warehouse for quantitative feeding. After the materials are

The belt feeder adopts H beam as the main frame, using steel tank as a leg, high strength and high stiffness, good stability.

This series of polishing machines is a new type of equipment: the granulating rate is more than 95%. The motor adopts flexible belt drive to start smooth, slow down the impact force and improve the service life of the equipment.

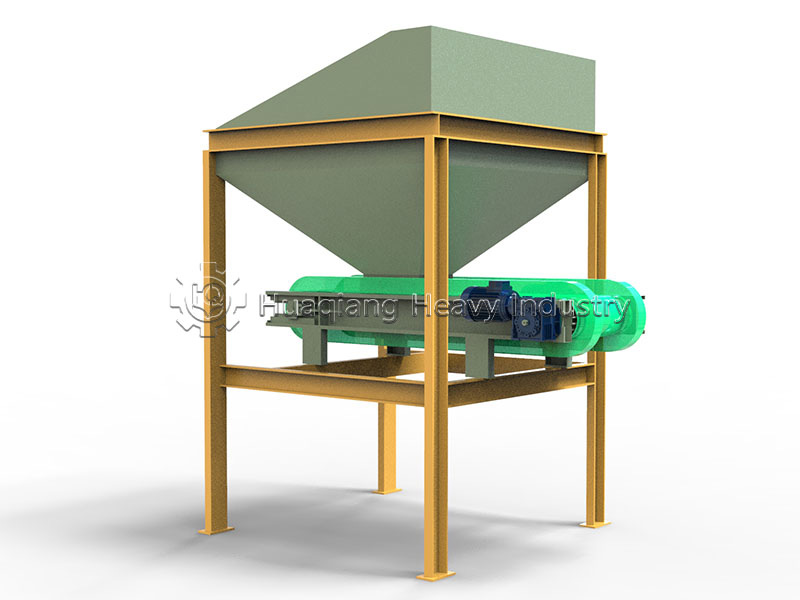

The machine is a new type of feeder. Its characteristic is that the shaft end of the reducer drives the stirring shaft to run. The stirring shaft has a fixed stirring tooth, and the stirring shaft drives stirring to make the material fully mixed.

Dust collector is a type of dust removal device. Each component of the dust collector has a certain size ratio. Each change in the proportional relationship can affect the efficiency and pressure loss of the dust collector.

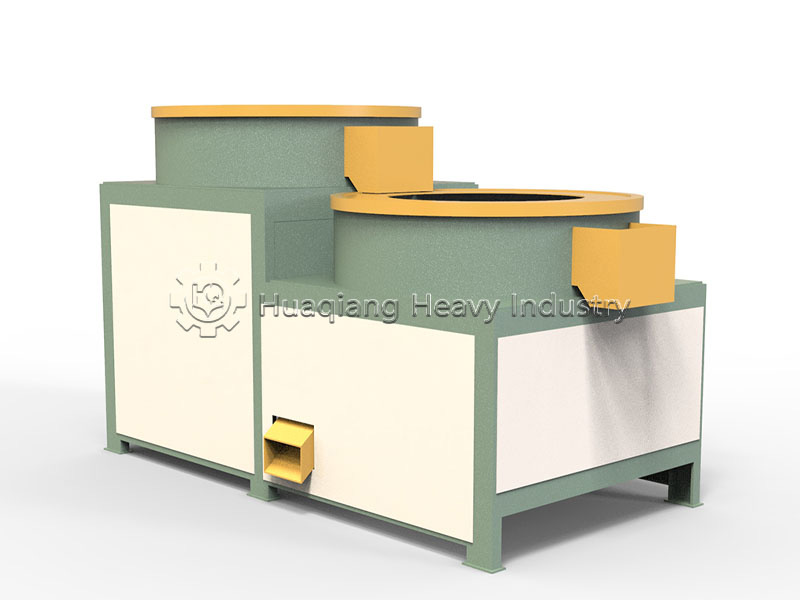

Gas/Oil Hot Air Stove,n the drying process and the wet granulation process, the hot air stove is a necessary related equipment, which provides the necessary heat source for the drier system.