Introduction of the npk,compound fertilizer production line:

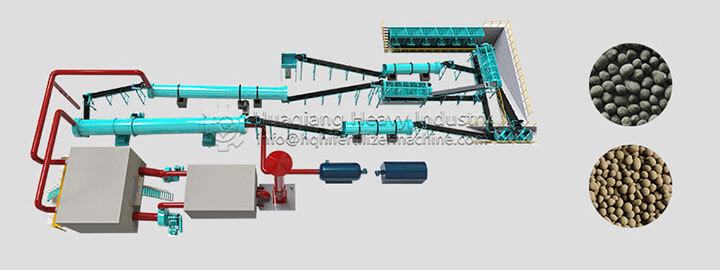

The process flow of the compound fertilizer production line can be generally divided into :raw material ingredients,raw material agitation,raw material granulation,granule drying,particle cooling,particle grading,finished product coating and final product packaging.The equipment has low investment,quick effect and good economic benefits.Thee complete equipment flow layout is compact,scientific and reasonable and advanced technology.Engery saving and consumption reduction,no waste discharge,stable operation,reliable operation and convenient maintenance.The raw material has wide adaptability and is suitable for granulation of various raw materials such as compound fertilizer,medicine,chemical industry and feed,and the product has high granulation rate.It can produce various concentrations,multiple types(including organic --inorganic compound fertilizer,biological fertilizer,etc.)compound fertilizer.

.jpg)

.jpg)

The main equipment that compound fertilizer production line contains:

1.Automatic batching machine

2.Belt conveyor

3.Mixer

4.Crusher

5.Rotary drum granulator

6.Dryer

7.Cooler

8.Screening machine

9.Coating machine

10.Automatic packing machine

Advantages:

1.This equipment has the less investment, good results and the great economic benefits.

2.Complete sets of equipment are compact, scientific and reasonable, and advanced in technology.

3.It can save energy , and has no waste discharge, stable operation, reliable operation and convenient maintenance.

4.The material has wide adaptability and is suitable for granulation of all kinds of raw materials such as compound fertilizer, medicine, chemical industry, feed and so on, and the product has high granulation rate.