In the production process of series of special fertilizers, inorganic nutrients and concentrated organic matter and trace element minerals are added according to different soil conditions and different crops, so that the fertilizer contains a variety of nutrient elements required for plant growth, such as nitrogen, phosphorus, potassium, sodium, manganese, zinc, copper, etc. According to the formula, the nitrogen, phosphorus, potassium and fermented materials are mixed by computer and transported to the granulator for granulation. The formula of organic and inorganic raw materials is mixed according to different series of products. Mix well in the mixer. If the proportion is 12%, about 12 tons.

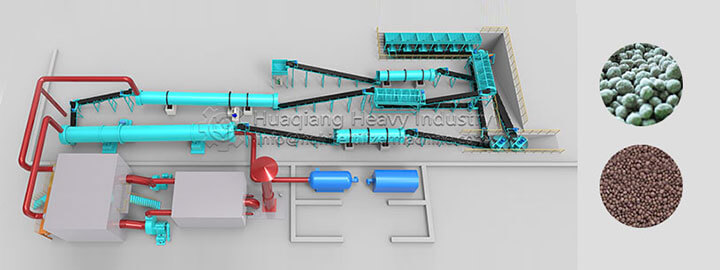

Pig manure bio organic fertilizer equipment is made from fresh pig manure and chicken manure as raw materials, which undergo a series of processing treatments to produce natural organic fertilizers. The pig manure bio organic fertilizer equipment requires two steps to process commercial organic fertilizers: the pre fermentation and treatment part and the deep processing and granulation part. The supporting equipment for pig manure bio organic fertilizer requires equipment such as fermentation turner, organic fertilizer crusher, drum screening machine, horizontal mixer, disc granulator, rotary dryer, cooling machine, screening machine, coating machine, packaging machine, conveyor, etc.

Organic fertilizer equipment has different equipment configurations based on different raw materials, and suitable plans can also be made according to investment budgets. The prices of organic fertilizer production machines vary with different yields. It is recommended that customers consider the investment amount for organic fertilizer production before making an inquiry, and then inform the manufacturer of the raw materials used for processing and production. This way, suitable production line configurations can be selected based on the budget.