How to produce the compound fertilizer using the fertilizer manufacturing technology?Why we to produce the compound fertilizer granulator?What advantages and disadvantages of the compound,npk fertilizer?

1.Definition of compound fertilizer:Compound fertilizer refers to the general term of fertilizer containing two or three important plant nutrient elements or N/P/K.Compound fertilizer contains n,p or N,K two main nutrient elements called binary comppound fertilizer.The compound fertilizer containig N/P and K is called temperary compound fertilizer.Some compound fertilizers contain not only the main elements of N,P and K but also many kinds of microelements.This kind of compound fertilizer is expressed by the total content of 20%,but the minmum content of each nutrient is not less than 4%,and the general total content is in the range of 25%-60%.The total content of 25%-30% is low concentration compound fertilizer,30%-40% is medium concentration compound fertilizer,and more than 40% is high concentration compound fertilizer.

The appearance of compound fertilizer is generally granular.Due to the different production process,the color is also different.Its main raw materials are ammonium sulfate,ammonium nitrate,ammmonikum carbonate,ammonium chloride,urea,potassium sulfate.

Advantages and disadvantages of compound fertilizer

Advantages of compound fertilizer:

1.The nutrient content is high and there are many main nutrient elements.The total amount of components of compound fertilizer is generally high,and there are many kinds of nutrient elements.Applying compound fertilizer at one time can supply at least two kinds of main nutrient elements for crops at the same time.

2.Less by-components and uniform structure.For example,ammonium phosphate does not contain any useless by-component,its anion and cation are the main nutrient elements absorbed by crops.The nutrient distribution of this kind of fertilizer is relatively uniform.Compared with the powdery or crystalline unit fertilizer,the structure of the fertilizer is close,the nutrient release is uniform,and the fertilizer effect is stable and long.Because of less-by-component,it has little adverse effect on soil.

3.Save storage and transportation costs and packaging materials.Because the compound fertilizer has less-by-component and higher effective component content than the unit fertilizer,it can save the cost of packaging,storage and transportation.For example,each ton of storage and transportation of ammonium phosphate is about 4 tons of storage and transportation of superphosphate and ammonium sulfate.

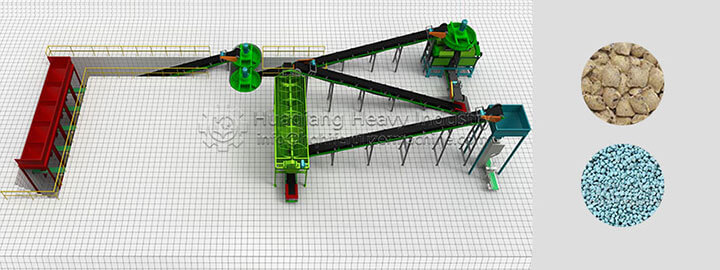

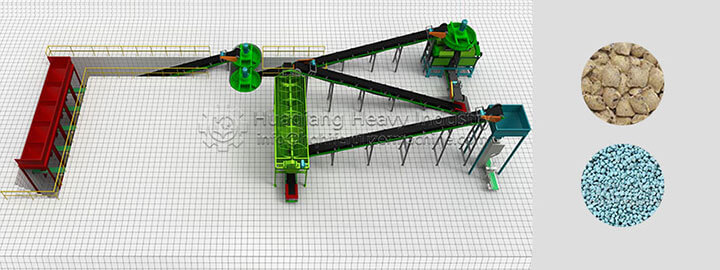

When producing the compound fertilizer,we generally produce the fertilizer into granulator or the powder.When producing the granulator,the

fertilizer granulator machine is the main organic fertilizer machine in the production process.Pelletilizing process by pelletilizing

The raw materials of single basic fertilizes such as urea,ammonium nitrate,ammonium chloride,ammonium sulfate,monoammonium phosphate,diammonium phosphate,bicalcium,procalcium,potassium chloride are crushed to the certain fineness,and the materials are agglomerated and graulated in the rolling bed of

rotary drum granulator or disc granulator by humidification and heating.In the process of granulation,the materials can also be agglomerated and granulated in the drum if conditions permit a small amopunt of phosphate phosphoric acid and ammonia are added to the granulator to improve the granulation conditions.NPK compound fertilizer products are obtained by drying,screening and cooling granulating materials,which is also one of the methods widely used in the world.In the early days,this method was used in the USA,India,Japan and other southeast asian countries.

This method has a wide range of raw materials,simple processing,less investment,low production cost,large production flexibility,simple and easy grade adjustment of products,strong universality,soild raw materials used and weak dependence on raw materials.Because it is a secondary processing process of basic fertilizer,there is almost no environment pollution.So this method is a better choice for most small and medium-sized producers.

Extrusion granulation process

Extrusion granulation using the

roller press granulator machine is a dry granulation process in which solid materials are are agglomerated by extermal pressure.It has the following advantages:

1.Generally,in the fertilizer manufacturing process does not need drying and cooling process,especially suitable for heat sensitive materials,while saving investment and engery consumption.

2.The operation is simple and there is no discharge of three wastes during production.

3.It can produce high concentration compound fertilizer with lower concentration than general compound fertilizer,and can also add organic fertilizer and other nutrient elements as needed.

However,the extrusion granulation method also has some shortcomings:a.as the key fertilizer equipment of roller press granualtion,the extruder consumes a lot of materials and has a high failure rate due to the problems of equipment manufacturing and materials of pressure parts.The production capacity of extruder is small,so it is difficult to achieve large-scale production.Therefore,this method is generally used for production scale below 30000 tons/year.