Before making an inquiry, you must first consider how much you want to invest in the production of organic fertilizer, and then inform the manufacturer of the raw materials for processing and production, so that you can provide you with an approximate price range, and then choose the appropriate production line configuration according to the estimated investment.

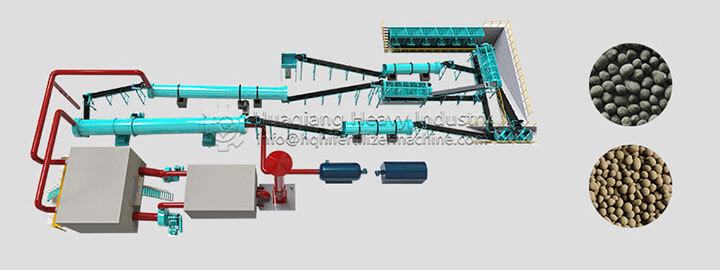

The organic fertilizer production line has three configurations: high, medium and low. Large fertilizer plants must adopt a complete set of production configurations, and the appearance and nutrient content of the finished products can meet the market requirements, and they have a greater advantage in the promotion of finished organic fertilizers.

The low-to-medium configuration organic fertilizer production line is suitable for small and medium-sized fertilizer factories. The sales scope of finished organic fertilizer is limited to nearby areas. Some processes in the organic fertilizer production process need to be completed manually.

High-configuration organic fertilizer production lines generally have NPK and organic fertilizer granulators, which can produce fertilizer granules. Fertilizer granules are conducive to storage and transportation. The sales scope of finished organic fertilizers is basically not restricted by regions.

In the fertilizer granulator, the cost of the roller press granulator is very low, but the material that can be granulated is abundant, and it can also be mixed with organic and inorganic granulation. The roller press granulator is an ideal fertilizer granulator with low input and high return.