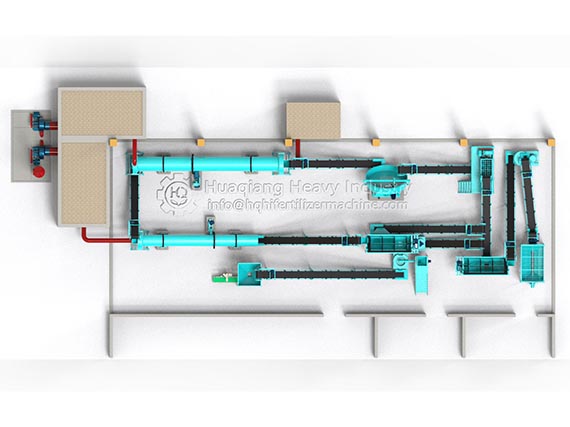

Disc granulator organic fertilizer production line process:

1. Grinding and mixing: the decomposing fermentation of organic fertilizer powder feed is crushed to achieve the appropriate particle size, and then transported to the mixing horizontal mixer, and the granulator conveyor is mixed to the feed bunker.

2. Disc granulation: the powder raw material is evenly fed into the hopper and evenly fed to the disc of the disc granulator; in the case of water content of the material, the water spray plate of the automatic disc

fertilizer granulation machine is sprayed on the surface of the material, so that the powder can achieve reasonable humidity; During the rolling process, the particles are rubbed and extruded to form relatively large particles of water organic fertilizer.

3. Drying and cooling: it is transported to the drum dryer by belt conveyor to roll the heat energy from the blown particles in the dryer for treatment, so as to realize the transformation of water rich particles from the drying hot stove. The drying water content of roasted granular organic fertilizer is reasonably transported to the cooler, which is cooled quickly in the cooler, and the cooled particles are sent to the screening, so as to improve the particle size.

4. Drum screening: drum screening machine, so that the organic fertilizer particles are coated through the conveyor belt of coater; unqualified particles are transported back to the mixing process after crushing and granulation.

5. Packaging and storage: the coated pellets are packaged and stored by the automatic weighing and packaging machine.

6. Dedusting process: drying, cooling and dedusting treatment plant, using cyclone separator or wet dedusting three-stage treatment water curtain, following the evacuation.

Advantages of disc organic fertilizer granulator

1. An adjustable particle size, relatively large degree of freedom. This is because the size of particles depends on the tilt and disc speed. The disc granulator can adjust the angle of tilt and rotation speed to control the wide range of particle size.

2. The disc granulator can directly observe the real-time granulation, the granulation process is abnormal and can be adjusted at any time.

3. For the short production line of organic fertilizer in the production process of disc granulator, the process is not complicated structure, and the equipment investment is relatively small, which is more suitable for small and medium-sized enterprises.