Compound fertilizers are classified according to their nutritional components: binary compound fertilizers and ternary compound fertilizers containing nitrogen, phosphorus, and potassium. Besides these three nutrient elements, those containing various trace nutrient elements are called multi-element compound fertilizers; additionally, some contain pesticides or growth regulators, referred to as multifunctional compound fertilizers. If classified by the dosage form of the fertilizer, it can be divided into solid compound fertilizers and liquid compound fertilizers, with solid compound fertilizers further divided into granular, powdery, and crystalline forms.

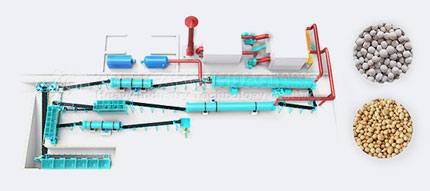

The production process of compound fertilizers is similar to that of organic fertilizers, roughly including collecting and processing raw materials; fermenting the fertilizer, which is often done using a fertilizer turning machine for high efficiency; then mixing with a fertilizer mixer, during which certain materials can be added as needed; followed by using a fertilizer granulator to manufacture the fertilizer into various shapes for easy storage and transportation; finally, drying and cooling, and packaging.

It is important to note that during production, regular maintenance of fertilizer production equipment should be performed to maintain optimal performance and prolong its service life. Additionally, it is crucial to reduce environmental pollution during production. For example:

Using enclosed fermentation spaces to reduce foul odors and harmful gas emissions during the treatment process and prevent air pollution;Establishing sewage treatment stations that use scientific methods to treat wastewater generated during production to ensure that the discharged water quality meets national standards and prevent water source pollution; Implementing sound insulation measures, such as installing soundproof walls or soundproof covers, to reduce the noise generated by mechanical equipment during operation and its impact on the surrounding environment; Rationalizing the planning of production areas to avoid occupying arable land or ecological protection areas, protecting natural resources and ecosystems; Providing employees with environmental knowledge training to enhance their awareness of environmental protection.

A scientific production process not only helps improve product quality and production efficiency but is also conducive to environmental protection and sustainable development. It promotes agricultural development while preserving green mountains and clear waters